System Monitoring

When it comes to efficiency, maintenance and the longevity of your hydraulics, system monitoring is one of the crucial and often forgotten keys. As advancements in the hydraulics industry have occurred, older machines tend to be left unloved, operating as they always have without any advancements in their monitoring systems, leaving manual gauges that are often forgotten to be looked at.

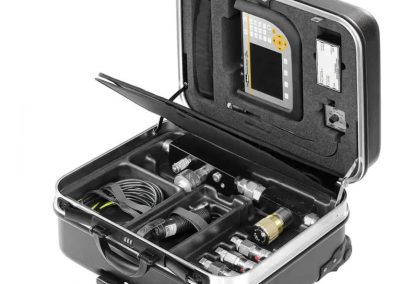

At Hydraulic & Pneumatic we understand the importance of system monitoring, with access to Parkers full range of mobile and fixed condition monitoring software and sensors, we can adapt new technology to work with your older machines or integrate our software with your newer ones.

The importance continual system monitoring is extremely important as it helps diagnose issues before they become apparent, catching small changes in system performance before anything is noticed visually during regular operation. This helps your prepare for maintenance, avoiding long downtimes and costly loss of production. On top of these benefits, system monitoring helps find areas of improvement, offering new insights to the running conditions of older machines, showing what needs to be improved.

On top of installing new monitoring systems, we also offer short term recording services. This helps give you a recorded baseline for machine performance, allowing you to compare past with current performance. Also giving you the opportunity to see a picture of your system operating, without having to pay for a full installation of new equipment.

Please, contact one of our branches today to see how we can help with any of your system monitoring problems.